- Coffee Packaging Bags

- Baby Food Packaging Bags

- Tea Packaging Bags

- Frozen Food Packaging Bags

- Protein Powder Packaging Bags

- Spice Packaging Bags

- Rice Packaging Bags

What are you looking for?

Back seal pouches are one of the most versatile packaging formats in the flexible packaging industry. Their defining characteristic lies in the single vertical seam that runs along the back of the pouch, providing a clean front and back surface for branding and product information. This seamless front design not only improves visual appeal on shelves but also enhances the efficiency of sealing and filling processes. The back seam allows for even weight distribution, making these pouches reliable for products requiring durability in storage and transport. Their structural design also supports various finishes and printing techniques, ensuring that businesses can align packaging with their branding strategies.

Back seal pouches are widely adopted because of their ability to balance cost-efficiency, functionality, and presentation. For food products, the secure seal provides protection against moisture, oxygen, and contaminants, ensuring longer shelf life and product safety. In non-food industries, such as household products or small hardware items, the back seal format offers strong packaging that can withstand handling and storage pressures. With Xlentpac’s 18 years of expertise in flexible packaging, these pouches can be customized to meet the specific needs of diverse industries, from snacks and powders to agricultural products. Their adaptability makes them a reliable option for both small-scale specialty items and high-volume mass-market goods.

When businesses decide on packaging, they often consider whether back seal pouches or other pouch styles better suit their products. The differences can be crucial in determining performance and consumer satisfaction.

Aspect | Back Seal Pouches | Other Pouch Formats |

Sealing Structure | Single vertical seam at the back, clean front | May include side gussets or multiple seams |

Shelf Appearance | Smooth branding surface on front and back | Sometimes interrupted by seams or gussets |

Storage Efficiency | Compact and easy to stack | Gusseted designs take more space |

Product Protection | Strong barrier against moisture and oxygen | Protection varies with design and material |

Cost-Effectiveness | Efficient to produce and fill | Often higher costs for complex structures |

This comparison highlights that back seal pouches deliver a balance of simplicity, strength, and visual clarity, making them especially appealing for companies that need efficient and visually attractive packaging solutions.

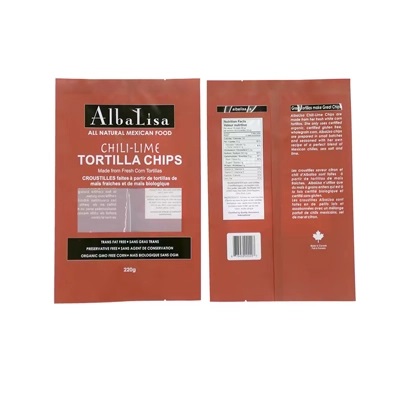

The versatility of back seal pouches makes them suitable for a wide range of applications. In the food industry, they are often used for snacks, coffee, spices, and frozen products, where freshness and presentation are equally important. In pharmaceuticals and health supplements, these pouches provide secure sealing and portioned packaging to maintain product integrity. Non-food applications, such as detergents, fertilizers, and small electronic accessories, also benefit from the durability and compact design of back seal pouches. Xlentpac, with its advanced workshops covering 38,000 m² and a workforce of over 300, ensures that these pouches can be manufactured to handle the technical demands of different industries, while maintaining consistent quality across large export volumes.

As global markets evolve, back seal pouches continue to adapt to emerging trends in packaging. Their ability to combine strength with efficient material use makes them a sustainable choice, especially as industries move toward reducing waste and improving recyclability. For brands aiming to stand out, the wide printable surface of back seal pouches creates opportunities for high-quality graphics and storytelling directly on the packaging. With companies like Xlentpac focusing on innovation and customization, back seal pouches are positioned not only to meet today’s packaging demands but also to support future developments in flexible packaging technology.

Hey, I'm Neo yan, sales & technical manager of Xlentpac.

An expert of flexible new material packging industry.

In the past 8 years, we provided flexible packaging solution for more than 60 countries and 200+clients in various industry such as food, snacks, pet food & cosmetic products.

The purpose of this article is to sharing knowlegde with readers.