- Coffee Packaging Bags

- Baby Food Packaging Bags

- Tea Packaging Bags

- Frozen Food Packaging Bags

- Protein Powder Packaging Bags

- Spice Packaging Bags

- Rice Packaging Bags

What are you looking for?

For food businesses, longer shelf life means fewer products thrown away and more sales.

It also reduces the risk of food poisoning, as spoiled food often contains harmful bacteria.

The key to longer shelf life is simple: stop bad bacteria from growing, slow down food's natural decay, and keep out dirt or moisture.

Food/Product Type | Packaging Structure | Performance Requirements |

Coffee/Tea/Seasoning Powder | PET/VMPET/PE OPP/VMPET/PE | Lightproof Flavor retention Air tightnessistatic |

Puffed Food | BOPP/VMCPP BOPP/VMPET/PE | Air tightness Lightproof Oil-resistant |

Candy/Biscuits/Dried Fruits | OPP/PE | High transparency Glossy/Economical |

Meat Products/Fish | PA/PE | Barrier property Puncture resistance Heat resistance |

Stand-Up Pouch for Liquids | PET/AL/PA/PE | Barrier property Pressure resistance Pollution resistance |

Frozen Food | PA/PE | Cold resistance Puncture resistance |

Retort Food | PET/AL/PA/RCPP | Barrier property Heat resistance |

Rice | KPA/PE | High tensile strength Low-temperature heat-seal |

Sterilization is the process of killing harmful bacteria in food. It’s one of the most important steps to extend shelf life. There are two main types: heat sterilization (traditional) and non-heat sterilization (gentler on food).

Low-Temperature Long-Time (LTLT): 62.8℃~65.6℃ for 30 minutes. Great for milk, juice, or beer. It keeps some natural flavors but only lasts a few days in the fridge.

High-Temperature Short-Time (HTST): 72℃~75℃ for 15-20 seconds. Better for fresh milk or juice—faster and keeps more nutrients.

135℃~150℃ for just 2-8 seconds. Kills all bacteria, including tough spores. When paired with sterile packaging (like Tetra Pak), food can last 6-12 months at room temperature. Perfect for long-life milk, bottled juice, or plant-based drinks (soy milk, oat milk).

121℃~135℃ under pressure (0.1~0.3MPa). Used for canned foods (like lunch meat, fish cans) or low-acid foods (meat, beans). It kills even the most heat-resistant bacteria, so canned foods can last 1-2 years.

Uses 400~600MPa of pressure for a few minutes. It breaks bacteria’s cell walls without heat. Perfect for cold-pressed juice, fresh salad, or cooked meat (like braised chicken feet). HPP food needs to be refrigerated and lasts 1-3 months.

Uses gamma rays or electron beams to kill bacteria and eggs. No heat, no chemicals, and no residue. Great for dry foods like nuts, grains, or dehydrated vegetables. It makes them last 6-12 months at room temperature.

Uses UV light (253.7nm wavelength) to kill bacteria on surfaces. Good for cleaning food processing rooms, packaging materials, or water. But UV light doesn’t go deep—only use it for surface sterilization.

Bacteria are the most common type of food contamination.

Some produce heat-resistant toxins, requiring a combination of thermal and non-thermal sterilization.

Bacteria Type | Common Contaminated Foods | Effective Inactivation Methods |

Salmonella | Poultry, eggs, dairy products, fresh fruits and vegetables | HTST sterilization at 72℃ for 15s Irradiation sterilization |

Staphylococcus Aureus | Meat products, pastries, salads, leftover food | HTST sterilization at Heat 70℃ for 30min high-pressure steam sterilization at 121℃ for 15min (destroys toxins) |

Escherichia Coli | Raw beef, raw milk, drinking water, vegetables | HTST sterilization Heat at 71℃ for 15s boil at 100℃ for 5min-thermal sterilization HPP (400MPa for 5min) UV flow-through sterilization |

Clostridium Botulinum | Canned foods, fermented meat products, vacuum-packaged foods | High-pressure steam sterilization at 121℃ for 20~30min (kills spores) |

Listeria | Low-temperature meat products, cheese, ice cream | Heat at 70℃ for 2min UHT sterilization (135℃ for 2s). UV sterilization (dose ≥3kGy) HPP ultra-high pressure (500MPa for 10min) |

Different foods have large differences in composition, water activity, and microbial sensitivity. The best storage conditions revolve around four core factors: temperature, humidity, light, and packaging method. Below is a classified storage guide for common foods, suitable for both home use and storage efficiency:

Fresh Meat & Seafood | Best Storage Condition | Shelf Life | ||

Fresh meat (pork, beef, lamb) | Refrigeration (0~4℃) Freezing (-18℃ or lower) | 1~2 days (refrigerated) 6~12 months (frozen) | ||

Seafood (fish, shrimp, shellfish) | Refrigeration (0~2℃) Quick freezing (-30℃ fast freezing, then transfer to -18℃) | 1 day (refrigerated) 3~6 months (frozen) | ||

Processed meat products (ham, sausage, bacon) | Unopened: Cool and dark place at room temperature. Opened: Refrigeration (0~4℃) | 6~12 months (unopened) 3~7 days (opened) | ||

dairy products | Best Storage Condition | Shelf Life |

Pasteurized fresh milk | Refrigeration (2~6℃), away from light | 3~7 days (refrigerated) |

Room-temperature milk (UHT sterilized) | Cool, dry, and dark place at room temperature | 6~12 months (unopened) |

Yogurt (refrigerated type) | Refrigeration (2~6℃) | 15~25 days (per package label, refrigerated) |

Cheese | Soft cheese: Refrigeration (2~4℃) >Hard cheese: Refrigeration (4~8℃) | 7~10 days (soft cheese) ~2 months (hard cheese) |

Butter | Refrigeration (0~4℃) / Freezing (-18℃) | 1~2 months (refrigerated) 6 months (frozen) |

Staple Foods | Best Storage Condition | Shelf Life |

Rice / Millet / Grains | Cool, dry place at room temperature sealed storage (with desiccant to prevent insects) | 6~12 months (unopened) 3~6 months (opened) |

Flour / Whole wheat flour | Cool, dry place at room temperature, sealed storage | 3~6 months (unopened) 1~2 months (opened) |

Bread / Steamed buns | Unopened: Room temperature Opened: Refrigeration (0~4℃) / Freezing | 2~3 days (room temperature) 1~2 months (frozen) |

Dried Goods & Condiments | Best Storage Condition | Shelf Life |

Nuts (walnuts, almonds, peanuts) | Unopened: Room temperature, away from light Opened: Refrigeration (0~4℃) Freezing (-18℃) | 6~12 months (unopened) 3~6 months (refrigerated) |

Salt / Sugar / MSG | Dry place at room temperature, sealed | Over 24 months (unopened) Over 12 months (opened) |

Snacks & Desserts | Best Storage Condition | Shelf Life |

Cookies / Potato chips | Cool, dry place at room temperature, sealed | 6~12 months (unopened) 1~2 weeks (opened) |

Chocolate | Refrigeration (10~15℃), sealed and away from light | 6~12 months (unopened) 2~4 weeks (opened) |

Candies / Preserved fruits | Cool, dry place at room temperature, sealed | 12~24 months (unopened) 3~6 months (opened) |

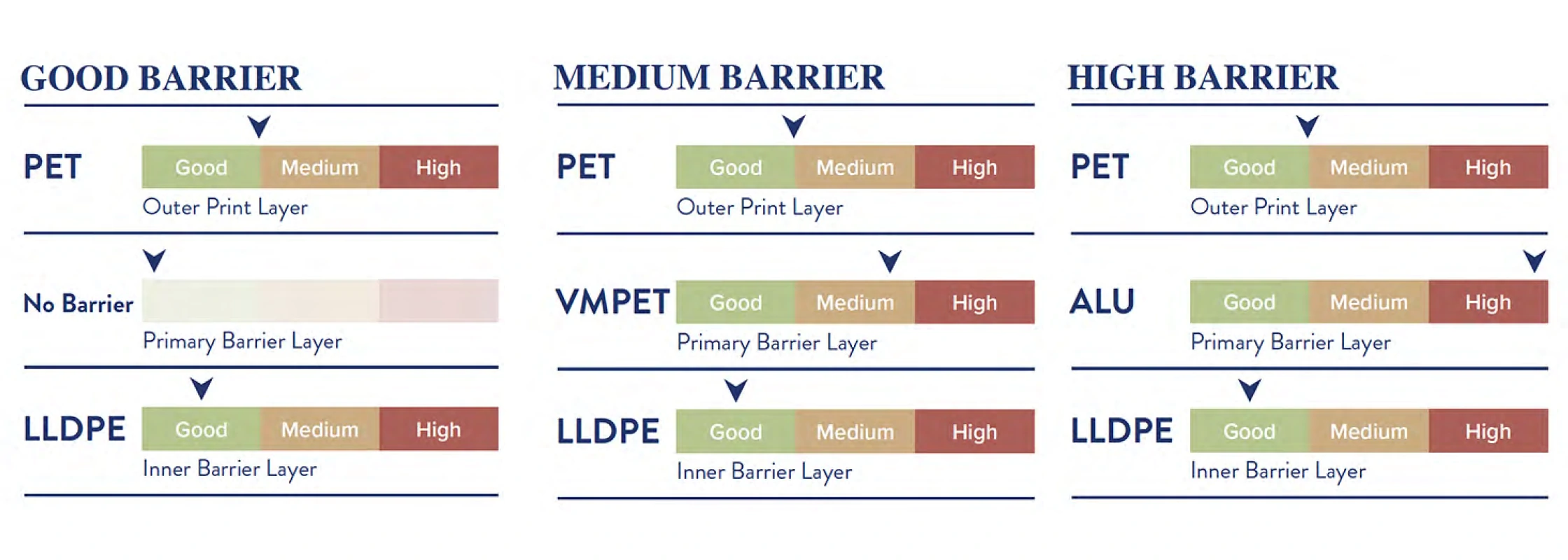

Image source: Kuraray

Image source: Kuraray

Vacuum packaging: Removes air to stop bacteria that need oxygen. Great for meat, nuts, or rice. It doubles or triples shelf life when paired with refrigeration.

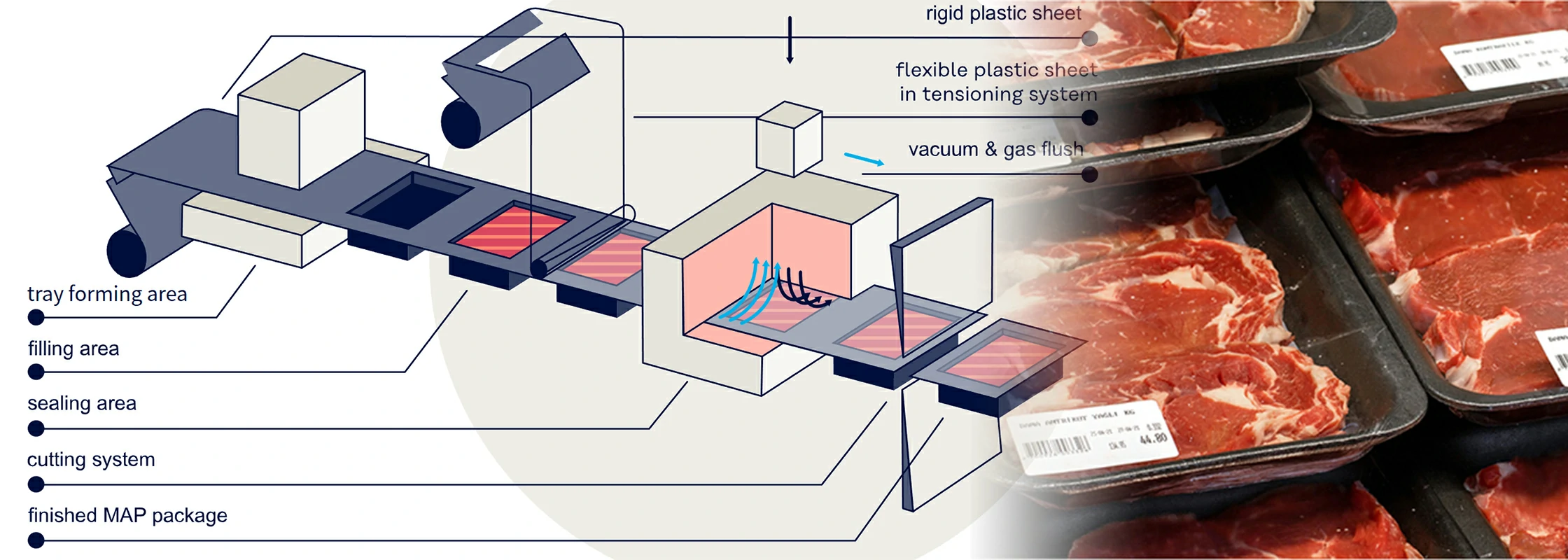

Gas-flushed packaging (MAP): Replaces air with nitrogen and carbon dioxide. Carbon dioxide kills bacteria; nitrogen keeps food from oxidizing. Use for fresh meat, salad, or baked goods—lasts 7-30 days in the fridge.

Tea polyphenols: Good for cooking oil or meat (fights oxidation and bacteria).

ε-Polylysine: Works for rice or pastries (stops harmful bacteria).

Natamycin: Prevents mold on cheese or bread.

Antioxidants: Vitamin C, vitamin E, or rosemary extract: Keep oils, nuts, or juice from turning bad. They’re natural and safe.

Extending food shelf life isn’t hard—you just need the right combination of packaging, sterilization, and storage. By following these tips, you can reduce food waste, save money, and keep your food safe to eat. Whether you’re storing snacks at home or running a small food business, these methods work for everyone.

In actual production, multiple methods are often combined to extend shelf life synergistically for example:

Fruit juice → HPP (High-Pressure Processing) sterilization + high-barrier aluminum foil bags + refrigeration.

Meat products → vacuum packaging + irradiation sterilization + addition of natural preservatives.

At Xlentpac, we understand that innovative packaging is the only way to make your brand stand out. Our team of experts is here to guide you through every step of the process, from design to delivery, ensuring your packaging is not just protection for your products, but a powerful marketing tool that communicates your brand's unique story.

Whether you're looking for sustainable solutions, cost-effective designs, or custom packaging that aligns with your brand's identity, we're ready to speak with you about your specific needs and how we can help you achieve your goals.

Contact us today to discuss your compliance needs or request supporting documentation.

Q: Which Packaging Bags Are Suitable for UHT Sterilization?

Tetra Pak, Structure: Composed of food-grade polyethylene (PE) + aluminum foil + kraft paper + polyethylene laminated structure

Combibloc,Structure: PE + aluminum foil + polyamide (PA) laminated structure

Q: Which Packaging Bags Are Suitable for HTST Sterilization

High-Barrier laminated Plastic Film Bags PE/PA or PE/EVOH-PE

Q: Which Packaging Bags Are Suitable for (HPP) Sterilization?

PET/EVOH/PA/PE four-layer composite. The middle layer EVOH is a high barrier material with better barrier properties than nylon.

Q: What’s the material structure of Retort Pouch?

PET/AL/NYLON/RCPP

Q: Can you do sterilization on the packaging bags?

Yes, usually we do Irradiation sterilization on bags if you need.

Hey, I'm Neo yan, sales & technical manager of Xlentpac.

An expert of flexible new material packging industry.

In the past 8 years, we provided flexible packaging solution for more than 60 countries and 200+clients in various industry such as food, snacks, pet food & cosmetic products.

The purpose of this article is to sharing knowlegde with readers.